stainless steel woven wire mesh is a versatile material with many applications. Its strength and durability make it invaluable in industries such as construction and manufacturing. But its optimal usage goes beyond mere selection. Understanding the nuances is essential for harnessing its full potential.

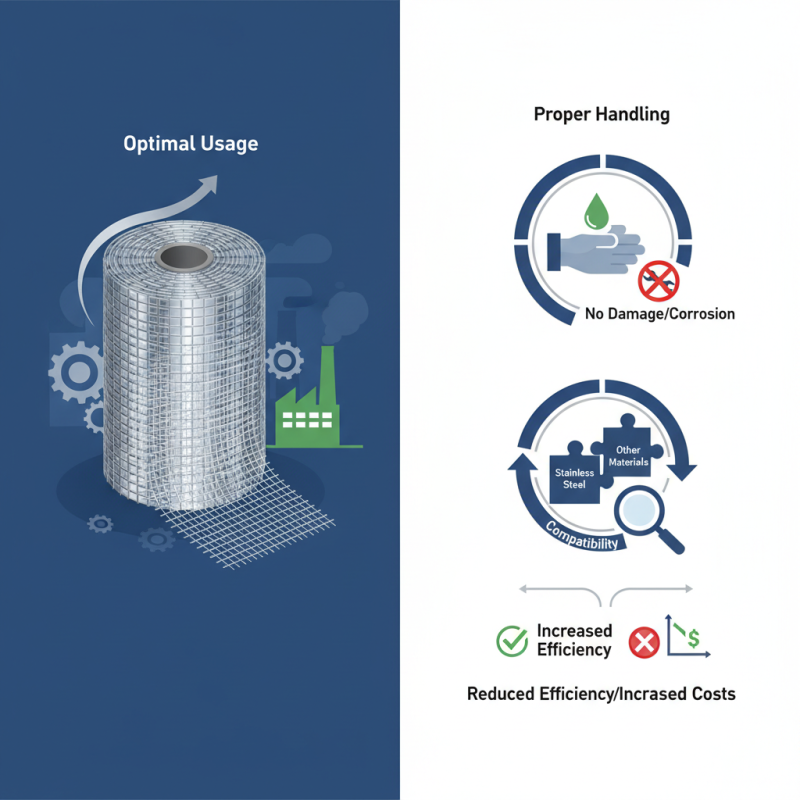

When using stainless steel woven wire mesh, several factors come into play. The mesh's weave pattern can greatly affect its performance. For instance, tight weaves are ideal for filtering, while looser weaves facilitate airflow. Choices matter. If not properly considered, one might face issues such as reduced efficiency or increased costs.

Pitfalls often arise during installation or maintenance. A lack of attention to proper handling can lead to damage or corrosion over time. Additionally, compatibility with other materials is crucial. Reflecting on these aspects can greatly enhance the effectiveness of stainless steel woven wire mesh in any project. Each choice leads to a different impact, urging a thoughtful approach.

When choosing stainless steel woven wire mesh, understanding the grade is crucial. Different grades offer varying levels of corrosion resistance, strength, and application support. For instance, stainless steel type 304 is popular for general use, known for its excellent corrosion resistance and moderate strength. However, this grade may not perform well in highly acidic or salty environments. Grade 316, on the other hand, excels in such conditions. According to industry reports, the 316 grade can withstand corrosion five times more effectively than 304 in marine settings.

The mesh's wire diameter also matters. Thicker wires generally provide more strength, which may be necessary for heavy-duty applications. Yet, thicker wires can result in reduced flexibility and may not suit every project. A recent survey highlighted that around 60% of users overlooked wire diameter, focusing solely on grade. This can lead to inadequate wire selection for specific applications, potentially causing long-term issues such as structural failure or premature wear.

Choosing the right stainless steel woven wire mesh involves more than just picking a grade. Users should also consider mesh pattern, opening size, and load requirements. Many professionals admit to struggling with these factors. Inadequate research often results in subpar results. Ultimately, blending a strong understanding of grades with practical application needs will lead to better outcomes in selecting woven wire mesh.

When choosing stainless steel woven wire mesh, understanding the weave patterns is essential. Different weaves affect strength, flexibility, and application. For example, a plain weave creates a robust structure, yet it can limit airflow. It’s ideal for filtration but may not suit decorative uses.

In contrast, twill weaves offer more flexibility. This pattern creates a softer finish, which can be appealing for architectural designs. Still, it may be less robust than plain weaves. Always consider how the mesh will be used. A slinky design might look good, but it may not hold up as well in harsh conditions.

Evaluating the right weave pattern is crucial. Misunderstanding these patterns can lead to suboptimal results. For instance, using a lighter mesh for heavy-duty tasks can be problematic. Take time to reflect on your specific needs before making a decision. Every weave has its pros and cons, and the choice affects performance significantly.

When discussing the durability of stainless steel woven wire mesh, various factors come into play. Material quality holds immense importance. High-grade stainless steel often leads to enhanced corrosion resistance. Research indicates that low-quality materials can reduce lifespan by 30% or more. This drastically affects performance in demanding environments.

Woven wire mesh design is also crucial. The weave tightness impacts strength and flexibility. A tighter weave generally offers better stability against mechanical stress. However, tighter weaves can also restrict airflow and drainage, which is something to consider.

Environmental conditions should not be overlooked. Exposure to extreme temperatures and humidity can lead to premature wear. Studies show that mesh used in coastal areas suffers from salt exposure, leading to corrosion within five years. Regular maintenance checks can help, but even the best care can't eliminate every risk. Users need to remain vigilant in monitoring their mesh’s condition.

To ensure the longevity of stainless steel woven wire mesh, proper maintenance is essential. Regular cleaning can help prevent buildup of dirt and grime. Use a soft brush and mild detergent. Rinse thoroughly with clean water afterward. Drying the mesh is also crucial. Air drying works fine, but excessive moisture can lead to corrosion.

Inspect the wire mesh periodically for any signs of wear or damage. Look for frayed edges or irregular weaves. If you notice any issues, repair them promptly. Ignoring these problems can lead to bigger failures down the line. Additionally, avoid using harsh chemicals that may degrade the steel finish. It’s a crucial point that often goes unnoticed.

Storage conditions are also critical. Keep the mesh in a dry, cool place when not in use. Humidity can promote rusting. Furthermore, consider covering the mesh to shield it from dust and debris. Small lapses in care might seem trivial at the moment but can significantly affect the mesh's lifespan. Refocusing on these details can lead to better overall performance.

Stainless steel woven wire mesh has several common applications across various industries. In construction, it serves as a vital component for reinforcement and partitioning. It enhances durability and maintains the structural integrity of buildings. Reports indicate that the construction sector accounts for approximately 30% of the global wire mesh market.

The food processing industry relies heavily on woven wire mesh for filtration and separation. This mesh type is crucial for ensuring the purity and quality of food products. It reduces contamination risks by capturing unwanted particles and debris. A study showed that about 40% of food safety incidents arise from inadequate filtration systems. This highlights the need for proper mesh selection based on application requirements.

In the mining industry, woven wire mesh plays a role in screening and separation processes. It affects efficiency and productivity directly. However, selecting the correct wire diameter and weave is essential for optimal performance. An oversight can lead to operational delays and increased costs. Regular assessments and adjustments are necessary to maintain standards. It’s important to remember that not all woven wire meshes are equal; quality and specifications matter greatly.

© 2022-2025 Pelican Lakes Resort & Golf, All rights reserved | Privacy Policy

BROUGHT TO YOU BY THE WATER VALLEY COMPANY